Unlocking the Power of UV Curing Lamps: A Complete Guide

2023-12-10

Discover the potential of UV curing lamps and how they can benefit various industries.

Introduction

UV curing lamps have revolutionized the way industries such as printing, automotive, and electronics manufacture their products. These lamps harness the power of ultraviolet light to rapidly cure inks, coatings, adhesives, and more. In this comprehensive guide, we will delve into the world of UV curing lamps, exploring their applications, benefits, and how to use them effectively.

What is a UV Curing Lamp?

UV curing lamps are devices that emit ultraviolet light to cure or dry materials instantly. The lamps emit high-intensity UV light, which initiates a photochemical reaction in the materials, leading to rapid curing. These lamps are widely used in various industries to speed up production processes and improve the quality of finished products.

How Do UV Curing Lamps Work?

UV curing lamps work through a process called photopolymerization. When exposed to UV light, the photoinitiators in the materials undergo a chemical reaction, causing them to cross-link and cure rapidly. This process results in a durable and high-quality finish, making UV curing lamps a popular choice for manufacturers looking to enhance their production processes.

Benefits of UV Curing Lamps

UV curing lamps offer a multitude of benefits for manufacturers. These lamps provide instant curing, reducing production times and increasing efficiency. Additionally, the use of UV light results in minimal heat generation, making them suitable for heat-sensitive materials. UV curing lamps also produce no volatile organic compounds (VOCs), making them an eco-friendly choice for businesses looking to reduce their environmental impact.

Applications of UV Curing Lamps

UV curing lamps are used in a wide range of industries, including printing, automotive, electronics, and medical device manufacturing. In the printing industry, UV curing lamps are used to instantly dry inks on various substrates, resulting in vibrant and durable printed materials. In the automotive industry, UV curing lamps are utilized to cure coatings on vehicle components, enhancing their durability and appearance.

Choosing the Right UV Curing Lamp

When selecting a UV curing lamp for your specific application, it's essential to consider factors such as the intensity of the UV light, the size of the curing area, and the type of materials being cured. Working with a trusted supplier can help ensure that you select the right UV curing lamp that meets your production needs.

FAQs

Q: Are UV curing lamps safe to use?

A: Yes, UV curing lamps are safe to use when operated according to the manufacturer's instructions. It is important to use proper protective equipment such as UV-blocking glasses and gloves when working with UV curing lamps.

Q: Can UV curing lamps be used on all types of materials?

A: UV curing lamps can be used on a wide variety of materials, including plastics, metals, glass, and more. However, it's essential to ensure that the materials being cured are compatible with UV light to achieve optimal results.

Conclusion

UV curing lamps have become an indispensable tool for manufacturers looking to enhance their production processes and achieve superior results. By understanding the benefits and applications of UV curing lamps, businesses can harness the power of UV light to improve their products' quality and efficiency.

In conclusion, UV curing lamps offer numerous advantages, such as rapid curing, eco-friendliness, and applicability to a wide range of industries. By incorporating UV curing lamps into their manufacturing processes, businesses can elevate their production efficiency and product quality. Whether in the printing, automotive, or electronics industry, UV curing lamps have proven to be a game-changer, setting a new standard for rapid and high-quality curing.

Recommended for you

VTECH for winning the "Technological Innovation Award" in the Equipment Category at the 2023

Vtech Co., Ltd. Showcases Cutting-Edge UV Curing Technology at ALLPack & ALLPrint Indonesia 2024

Vtech Exhibits Cutting-Edge UV Curing Technology at The 21st International Plastic, Printing and Packaging Industry Exhibition

Бренд ведущих производителей светодиодных систем отверждения в Китае

Top-Tier UV LED Curing Systems Manufacturers in Europe

Vtech Shines at Drupa 2024, Showcasing Industry-Leading UV Curing Technology

You may also like

Offset LED pre-press testing machine

An LED pre-press testing equipment that can be widely used in schools, printing plants, and R&D institutions. It can test the curing conditions of various inks and products using LEDs. The LED band can be customized according to customer needs.

Water-cooled UV Curing Equipment

UV curing equipment is equipment that uses UV technology in the field of curing. It consists of UV light source system, cooling system and circuit control system.

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Specially designed for offset printing machines, it can cure traditional UV ink. It has the characteristics of fast curing speed, low curing temperature, safety and environmental protection, long service life and good film-forming performance.

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

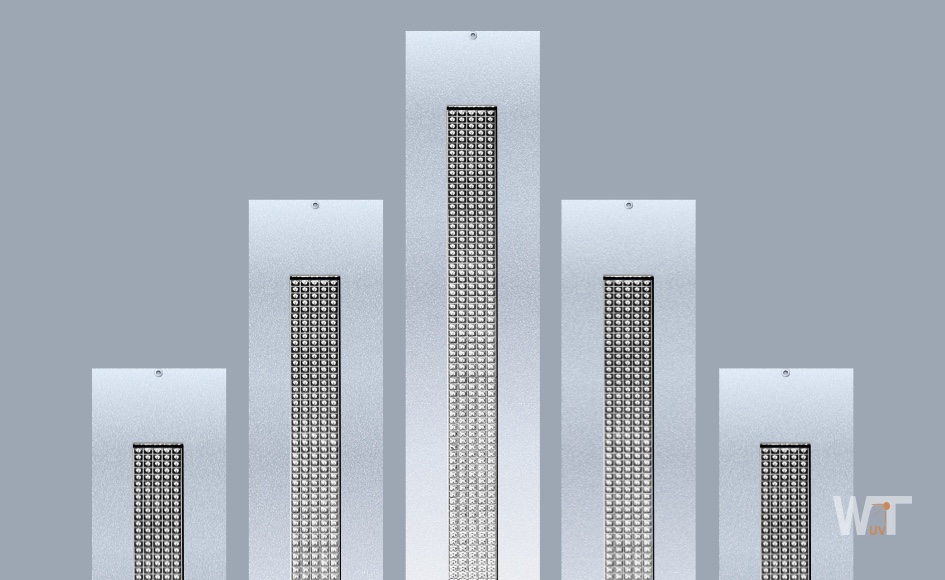

Three traditional UV lamps and cassettes equipped with control cabine and cooling device, is used for curing inks using UV radiation sources.

Get in touch with us

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code