WT Solution

LED-UV curing system for screen / offset UV ink with many LED-UV modules

WT a leading company specializing in ultraviolet (UV) and LED curing technology, dedicated to delivering efficient UV curing solutions to various industries.

With years of experience and expertise, we offer innovative UV curing equipment, lamps, accessories, and services to our clients.

Exporting countries

30

Completed projects

1000+

Years of experience

17

Equipment Description

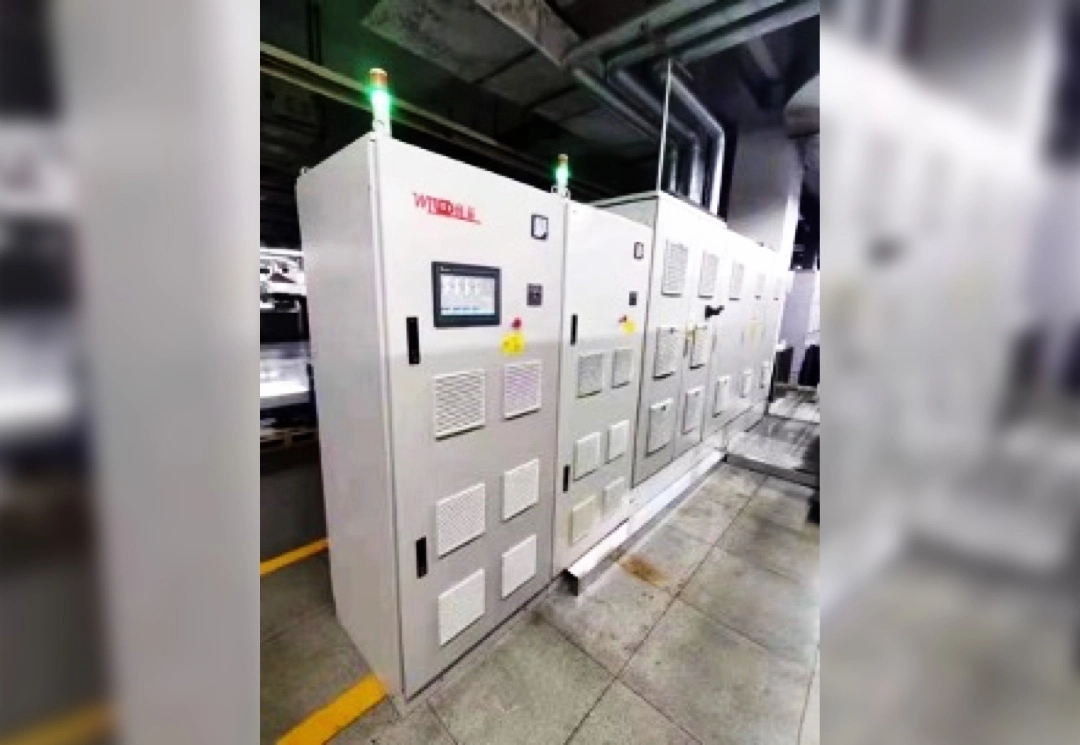

Two LED UV modules with replaceable LED UV elements (Fig. 1), equipped with control cabinet and cooling device (Fig. 2), is used for curing inks using LED radiation sources.

|

Chiller System Includes: |

Protection devices such as: |

2. Weihui cooling fan. |

1. Cooling liquid level control device 2. High and low voltage control device 3. Flow(stream) detector |

LED-UV module parameters:

1. Smooth adjustment of UV radiation power in the range from 0 to 100%.

2. The operation of LED UV module is controlled using a touch screen with a one-touch interface.

3. LED UV elements operate only after signal confirmation from the feeder board sensors and cylinder impression-ON signal. Thus, LED UV module starts working only when printing starts. LED UV elements are completely turned off during the standby mode.

4. The system warns if the cooling liquid level is low, or if maintenance of cooling unit is required, or if the flow sensor detects a leakage.

Equipment Components

|

Item |

№. |

Description |

Manufacture |

Specification |

|

1 set of cabinet 1950*800*600 |

1 |

400V DC Power supply |

Meanwell |

400V |

|

2 |

Switcher |

MEANWELL |

-- |

|

|

3 |

Relay |

Mistubishi |

40В |

|

|

4 |

AC contactor |

CHNT |

3210 |

|

|

5 |

PLC |

Mitsubishi |

FX3U |

|

|

6 |

Touch screen |

DELTA |

10” |

|

|

7 |

Cabinet box |

WT |

195*80*60cm |

|

|

8 |

Leakage switch |

ABB |

XT1N160 |

|

|

1 set of Chiller |

9 |

Compressor |

Panasonic |

8HP |

|

10 |

Water pump |

Nanfang |

-- |

|

|

11 |

Cooling fan |

WENHUI |

-- |

|

|

LED module (cassette) |

12 |

LED module |

Seoul |

42.5*80*3mm |

|

13 |

Quart |

JINGZHOU |

900*3mm |

|

|

14 |

The outer cassette with water connectors |

WT |

820*80mm light window |

Main Specification

|

Curing speed: |

10000 sheets/h |

Curing width: |

820nm |

Input voltage: |

380V / 50Hz |

|

UV wavelength: |

385nm |

Power consumption: |

32 kW (2 х UV LED module, 16 kW each) |

Chiller power consumption: |

8HP |

|

Total power consumption: |

40KW |

Electrical connection: |

Wire cross-section 30mm², 3 phases, 5 power lines (3 lines are the main power lines, 1 line is zero, 1 line is ground). |

||

|

Weight and dimensions with no packaging: |

• LED module: 90cm(L)*12cm(W)*8cm(H), weight 20kg • Cooling unit: 159cm(L)*75cm(W)*135cm(H), weight 380kg • Main control cabinet: 80cm(L)*60cm(W)*195cm(H), weight 300kg |

||||

|

Weight and dimensions with packaging: |

• Wooden box with control cabinet :120W*210H*65cmL, weight 330kg • Wooden box with cooling unit: 175H*90W*170L cm, weight 430kg • Wooden box with two cassettes and wire and cable . 40cmH*90cmW*1100cmL weight 150kg |

||||

Water-cooled UV Curing System

The water-cooled UV curing system is an advanced ultraviolet (UV) curing technology that efficiently lowers the temperature of UV lamps through water circulation, ensuring system stability during prolonged operation.

Efficient Curing: The water-cooled design ensures that UV lamps operate at a constant low temperature, improving curing efficiency. It is suitable for the rapid curing of various coatings and inks, reducing production time.

Energy Efficiency and Environmentally Friendly: Water-cooled systems are more energy-efficient compared to air-cooled systems, reducing energy consumption. Additionally, they help reduce heat radiation from UV lamps, providing a more comfortable working environment.

Temperature Control: With precise temperature control, the system operates within an optimal temperature range, providing consistent curing results. This helps reduce waste and enhance product quality.

LED UV Curing System

The LED UV curing system is an efficient photopolymerization technology that utilizes UV LED light sources and finds wide applications in printing, coating, electronics manufacturing, and more. It is characterized by its fast curing speed, low energy consumption, and eco-friendliness, significantly improving production efficiency while reducing energy consumption and environmental pollution.

Energy-efficient and eco-friendly: Compared to traditional mercury lamp curing, LED UV systems have lower energy consumption, reducing energy waste, and emitting no harmful mercury, making them environmentally friendly.

Precise control: Enables precise control of the curing process, improving product quality.

Durable and reliable: LED light sources have a long lifespan and high stability, reducing downtime.

Card Printing Technology

Card printing technology is an advanced printing technique known for its unique features such as foil stamping, embossing, and holographic effects. Through this process, we can give cards an impressive and distinctive appearance.

Foil stamping allows the addition of metallic or colored layers to the surface of the card, making it more visually striking. Embossing, on the other hand, creates raised or recessed patterns and text on the card by applying pressure, enhancing the tactile feel and quality of the card. Holographic effects involve special printing techniques to create a three-dimensional visual effect, adding vibrancy to the card.

The key characteristics of this printing technology lie in its high level of customization and sophistication. Each card can be tailored to the specific preferences of the client, resulting in unique and personalized creations. With distinctive foil stamping, embossing, and holographic effects, cards become not just a means of conveying information but also works of art.

Our Advantages

It is characterized by its fast curing speed, low energy consumption, and eco-friendliness, significantly improving production efficiency while reducing energy consumption and environmental pollution. Additionally, the LED UV curing system can be used to cure various materials, such as inks, coatings, adhesives, providing reliable curing solutions for various industrial applications.

Feel Free To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs. Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang