Our Applications

UV Curing Printing Applications

WT has a wealth of experience in the design and manufacture of UV curing solutions across a wide range of applications in the printing, coating and converting industries.

From the drawing board, WT UV systems are conceived to perfectly integrate into the wider system; working at optimum efficiency and with the highest reliability to reduce operating costs, environmental impact and unscheduled downtime.

Below is a brief outline of each of the main UV curing printing applications, including further details on which WT products are best suited to each application:

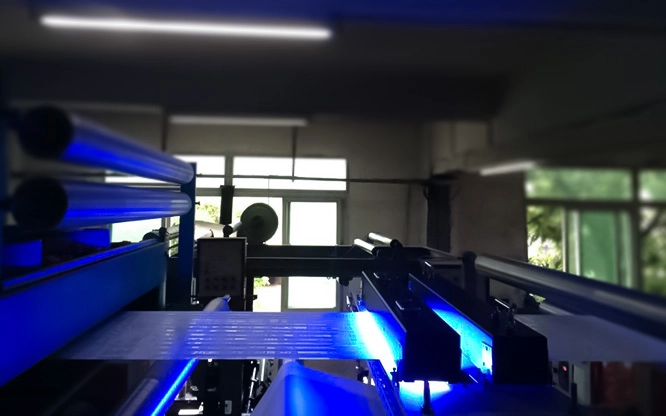

UVLED System for Offset / Rotogravure Press

The UV LED system for label press utilizes UV LED light sources to provide an efficient, low-energy solution for label printing. It instantly cures the ink without the need for hot air or extended drying processes, greatly enhancing production efficiency. Additionally, UV LED systems reduce energy consumption and maintenance costs, as LED lamps have a longer lifespan and do not require regular tube replacements.

Label Printing: UV LED systems are widely used in the label printing industry to produce high-quality labels for applications such as food packaging labels, cosmetic labels, and medical product labels.

Packaging Printing: UV LED systems are also used for printing various types of packaging materials, including cardboard boxes, plastic bags, and packaging films.

Signage Production: UV LED systems are used to produce durable signs and plaques, including road traffic signs and corporate signage.

Specialty Material Printing: UV LED systems are suitable for printing various specialty materials, including metals, glass, and ceramics.

Interdeck LED

Water-cooled LED UV system

Roland 709

UV Cassettes on EOP

UV Cassettes on EOP (End of Press) is an advanced technology used for environmental pollution control. It consists of UV lamps and an EOP is employed to remove harmful pollutants from both air and water. This technology utilizes the radiation of ultraviolet light and chemical reactions from electron oxidation to decompose and eliminate hazardous compounds, thereby improving air and water quality.

Air Purification: UV Cassettes on EOP finds wide applications in indoor and industrial settings to eliminate volatile organic compounds (VOCs), odors, and bacteria, among other harmful substances, providing fresher indoor air.

Water Quality Enhancement: This technology is also used for wastewater and drinking water purification, helping to remove microorganisms, heavy metals, and organic pollutants from water to ensure water quality and safety.

Industrial Applications: UV Cassettes on EOP plays a crucial role in industrial production by treating exhaust gases and wastewater, reducing emissions and pollution in industrial processes.

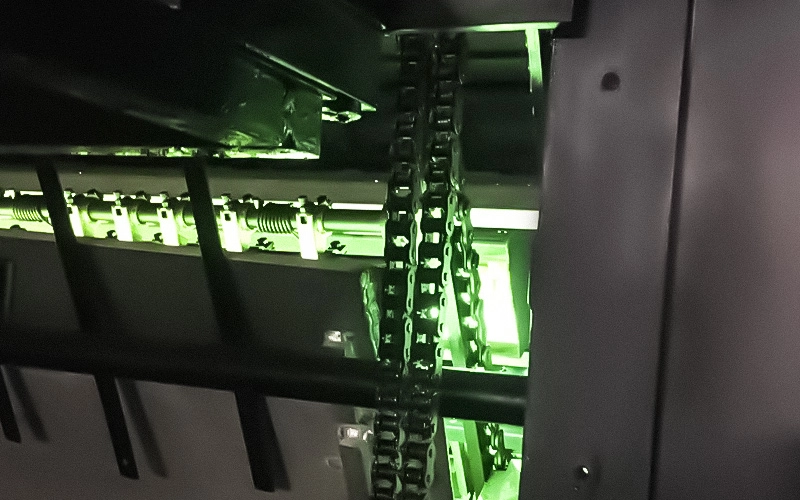

UV Cassette in ID (Interdeck)

UV Cassette in ID (Interdeck) is a critical equipment used in the printing industry for UV curing during the printing process. This device is typically positioned between the printing units of a printing press and is used to instantly cure inks or coatings using ultraviolet (UV) light radiation after the application of printing ink to the substrate. This UV curing technology allows for the rapid drying of ink, leading to increased production efficiency and improved print quality.

Printing Industry: UV Cassette in ID (Interdeck) is primarily employed in the printing industry, especially when producing high-quality labels, packaging, and publications. By using UV curing during the printing process, it enables faster production speeds and excellent printing results.

High-Speed Production: This technology is suitable for tasks that require high-speed production as it allows for almost immediate curing of ink or coatings on the surface of printed materials, ensuring exceptional print quality even at high production speeds.

Quality Assurance: UV Cassette in ID (Interdeck) ensures the curing of ink on the surface of printed materials, resulting in durability, gloss, and vibrant colors of the printed products.

Cabinets for UV LED System

Cabinets for UV LED System are specialized equipment designed for the installation and management of UV LED curing systems. These cabinets typically feature robust structures and internal configurations suitable for UV LED system components, including power supplies, control units, and cooling equipment. They provide an efficient, safe, and easy-to-maintain solution for UV LED system management.

Printing and Coating: Cabinets for UV LED System are primarily used in printing, coating, and UV curing applications. They can accommodate various components of UV LED systems and ensure their proper operation. This is crucial in the printing and coating industry as UV curing accelerates the drying of inks and coatings, enhancing production efficiency.

Medical Device Manufacturing: In the field of medical device manufacturing, Cabinets for UV LED System are employed to cure coatings on medical equipment. This helps ensure the required durability and longevity of medical devices' surfaces.

Electronics Manufacturing: In electronics manufacturing, these cabinets can be used for UV curing electronic components and printed circuit boards. UV curing enhances efficiency and quality in electronic manufacturing.

Feel free to contact us with any questions you have.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs. Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

Unsure which UV curing system is best for you?

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code