WT Products

Products Series

WT is a professional R&D and production of water cooled UV curing system, LED UV curing system enterprises.

WT has an array of UV lamp and LED products to meet almost any printing or converting need. All products can be integrated seamlessly by WT to fit your machine.

WT Products

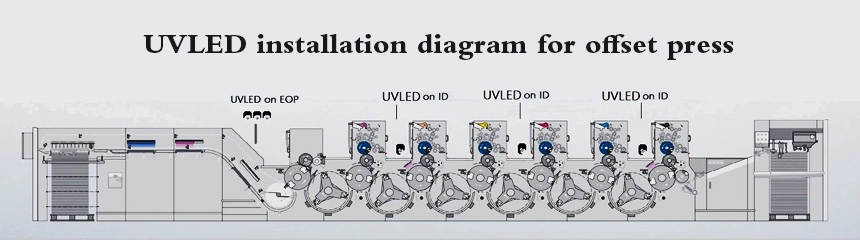

UV LED Systems

Curable traditional UV ink, dedicated for offset printing machines.

UV offset ink / UV gravure ink / UV flexo ink

UVLED system is a single wavelength light source in ultraviolet curing, generally using 365nm-405nm wavelength UV light to cure ink layer.

WT's LED water cooling system uses a plane lens, no curved surface refraction, no loss of light intensity, one time of concentrating to parallel distribution of focus points, no secondary refraction into a line, which increases the light intensity by more than 30%, no color difference between the ink layers after curing, the paper temperature is kept at room temperature, and the curing is thorough for Uv inks.

Efficient Curing: UV LED Systems utilize high-intensity UV light sources to instantly cure printing inks, enhancing production efficiency.

Energy saving and environmental protection: Compared to traditional mercury lamps, UV LED systems are more energy-efficient and do not require heating or cooling time, reducing energy waste.

Low Heat Radiation: UV LED systems produce minimal heat radiation, making them suitable for temperature-sensitive printing materials and reducing thermal stress.

WT Products

Traditional UV Curing System

Tradition UV Systems pioneering the UV Water-cooled technology in the industry, we provide efficient and reliable UV curing solutions for the printing process. Our UV systems have outstanding applications in various fields such as offset press, label printing, gravure press, and flexo, offering diversified choices to our customers.

Additionally, UV Lamp Systems are used for rapidly curing coatings, paints, and adhesives, thereby increasing production efficiency.

Due to their efficiency, environmental friendliness, and energy-saving advantages, UV Lamp Systems find wide applications in food processing, healthcare, industrial production, and more.

WT Products

UV Water-cooled Lampshade

UV Water-cooled Lampshade is an efficient cooling device designed for ultraviolet (UV) lamps, commonly used in industrial and laboratory applications. It employs advanced water-cooling technology to effectively reduce the temperature of UV lamps, extending their lifespan and enhancing performance.

UV Water-cooled Lampshades not only ensure the stability of UV lamps during high-intensity operation but also help minimize the heat impact on the surrounding environment. These devices are typically easy to install and maintain, making them suitable for various applications that require reliable UV irradiation.

Mechanical Parameters:

WT Products

WT UVLED Advantages

UVLED is an advanced ultraviolet light curing technology widely used in printing, coating, and curing applications. The working principle of UVLED involves generating ultraviolet light through Light Emitting Diodes (LEDs), enabling the instant curing of coatings or inks. Compared to traditional UV light sources, UVLED offers numerous advantages.

1. Intelligent.

2. Get rid of powder spray and film laminated.

3. Saving your preparation time.

4. Realize artcrafts on paper surface by UV inks such as UV coating, cast & cure etc.

WT Products

Film Printing

PP、OPP、PE Flexo UV Printing and Curing.

Film Printing is a traditional printing process that involves applying ink or pigments onto special films and then transferring the image onto various types of materials such as paper, plastic, or textiles.

Film Printing is commonly used for producing high-quality printed materials like brochures, posters, packaging, and labels. It is known for its ability to capture fine image details, vibrant color saturation, and long-term durability, making it still popular in some specialized applications.

1. Film Printing achieves high-resolution printing, ensuring clear and detailed patterns and text.

-

2. The technology is suitable for various types of film materials, including polyester film, polyethylene film, etc., making it widely applicable across different industries.

-

3. Products printed with Film Printing exhibit strong durability, resisting friction and wear, making it suitable for products that require longevity.

-

4. Film Printing supports personalized design and customization, making products visually appealing and meeting diverse market demands.

-

5. Film Printing can also choose environmentally friendly materials and printing processes, aligning with modern societal demands for sustainability.

WT Products

Spareparts

We offer kinds of UV / LED spareparts

We offer a variety of UV/LED spare parts to ensure your equipment operates at its best. These spare parts include key components for UV and LED systems designed to enhance the performance and longevity of your equipment.

Our spare parts are designed to enhance the performance of UV and LED systems, ensuring excellent results under various working conditions.

UV accessories are all accessories used in UV process equipment, such as UV lamps, UV lampshades, UV plugs, UV color separation sheets, etc. For example, our company's UV lamps are ozone-free, low in heat, and have a warranty of more than 1,500 hours.

In addition to providing spare parts, we offer comprehensive support and services to ensure you have the best experience during usage.

Whether you're looking for replacement parts or considering an upgrade for your equipment, we can meet your needs. Feel free to contact us for more information about our UV/LED spare parts.

Offset LED pre-press testing machine

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Feel Free To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs.

Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code