This UV indicator on line is the first one installed on Roto-gravure press in China

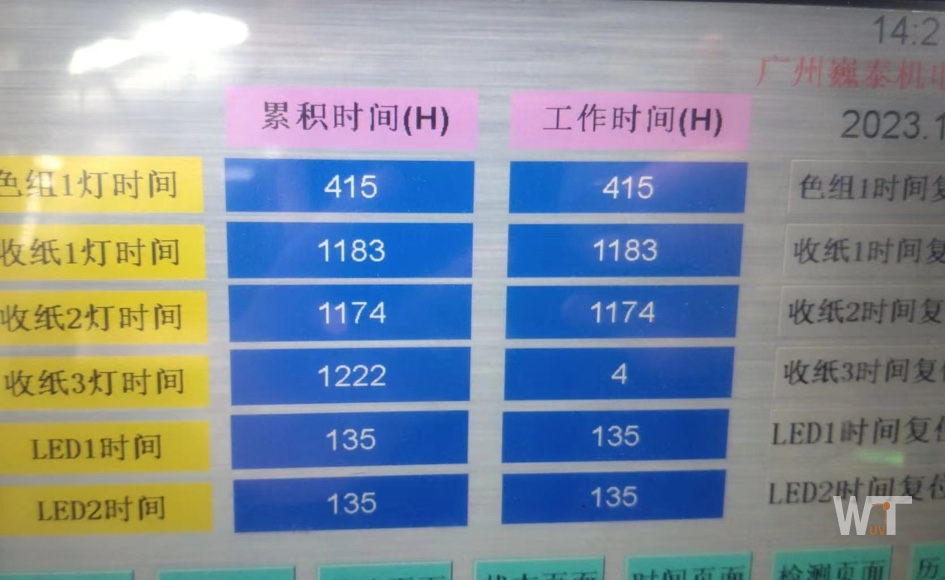

WT's UV lampshade is designed with water-cooled and air-cooled composite cooling, which greatly improves the service life of UV lamps and can reach more than 1500 hours. Another BOBST Roto machine is equipped with a water-cooled UV curing system. It is also the first set of equipment to add an online energy meter, which can monitor the energy of the UV lamp in real time. It is the first set in China.

The printing industry in China has seen a significant technological advancement with the recent installation of the first UV indicator on a rotogravure press. This innovative addition to the press has revolutionized the way printing is done, setting a new standard for efficiency and quality in the industry.

UV System on the BOBST Rotogravure Press with 200/min.

The UV system that has been installed on the rotogravure press is a game-changer for the printing process. It is integrated into the Bobst press, which operates at an impressive speed of 200/min. This state-of-the-art technology allows for enhanced curing and drying of inks, leading to faster production and improved overall print quality.

Impact on Printing Efficiency

The installation of the UV system on the rotogravure press has significantly increased printing efficiency. With the ability to cure and dry inks at a faster rate, the press can now handle larger volumes of work in a shorter amount of time. This has allowed printing companies to meet tight deadlines and take on more projects, ultimately boosting their productivity and profitability.

Quality Improvement with UV Indicator

In addition to the increase in efficiency, the UV indicator has also led to a notable improvement in print quality. The enhanced curing and drying process ensures that the inks adhere to the substrate more effectively, resulting in sharper and more vibrant prints. This has been a game-changer for businesses that rely on high-quality printing to set themselves apart in the market.

The Significance of the UV Indicator

The installation of the UV indicator on the rotogravure press marks a significant milestone in the printing industry in China. It represents the continuous innovation and advancement within the sector, demonstrating a commitment to staying ahead of the curve in technology and processes. This development has put China on the map as a leader in printing technology.

UV lamps and can reach more than 1500 hours.

FAQs

Q: What is a UV indicator?

A: A UV indicator is a device that measures and monitors the UV light intensity during the curing and drying process in printing.

Q: How does the UV indicator benefit printing companies?

A: The UV indicator ensures consistent and optimal UV light exposure, resulting in better quality prints and increased efficiency.

Q: Can the UV indicator be integrated into other printing presses?

A: Yes, the UV indicator can be integrated into various types of printing presses to enhance their performance.

Conclusion

The installation of the UV indicator on the roto-gravure press in China has made a significant impact on the printing industry. With improved efficiency, enhanced print quality, and a demonstration of technological leadership, this development paves the way for future innovations in printing technology.

VTECH for winning the "Technological Innovation Award" in the Equipment Category at the 2023

Vtech Co., Ltd. Showcases Cutting-Edge UV Curing Technology at ALLPack & ALLPrint Indonesia 2024

Vtech Exhibits Cutting-Edge UV Curing Technology at The 21st International Plastic, Printing and Packaging Industry Exhibition

Бренд ведущих производителей светодиодных систем отверждения в Китае

Top-Tier UV LED Curing Systems Manufacturers in Europe

Vtech Shines at Drupa 2024, Showcasing Industry-Leading UV Curing Technology

You may also like

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code