Shining a Light on UV/LED Curing: A Breakthrough Technology in Material Curing

UV/LED curing systems are widely used in various industries, including printing, automotive, electronics, packaging, and woodworking. These systems play a crucial role in the drying, hardening, and curing of materials by utilizing ultraviolet (UV) or light-emitting diode (LED) technology.

UV/LED curing systems consist of a light source, such as UV lamps or LED arrays, and a power supply unit. The light source emits high-intensity UV or visible light, which triggers a photochemical reaction in a special photoinitiator present in the material to be cured. This reaction instantaneously transforms the liquid or semi-solid material into a solid state.

One of the major advantages of UV/LED curing systems is their high speed of operation. Traditional curing methods, such as heat or air drying, can take a long time to complete. UV/LED curing, on the other hand, achieves instant curing, significantly reducing production cycle times. This is particularly beneficial in high-volume manufacturing processes.

UV/LED curing systems also offer exceptional control over the curing process. The intensity and duration of the light emitted can be adjusted to meet specific requirements. This versatility allows manufacturers to ensure consistent quality and achieve precise curing results.

Additionally, UV/LED curing systems are environmentally friendly compared to alternative curing methods. They do not emit harmful volatile organic compounds (VOCs) or generate excessive heat, making them ideal for use in sensitive applications, such as food packaging or medical device manufacturing.

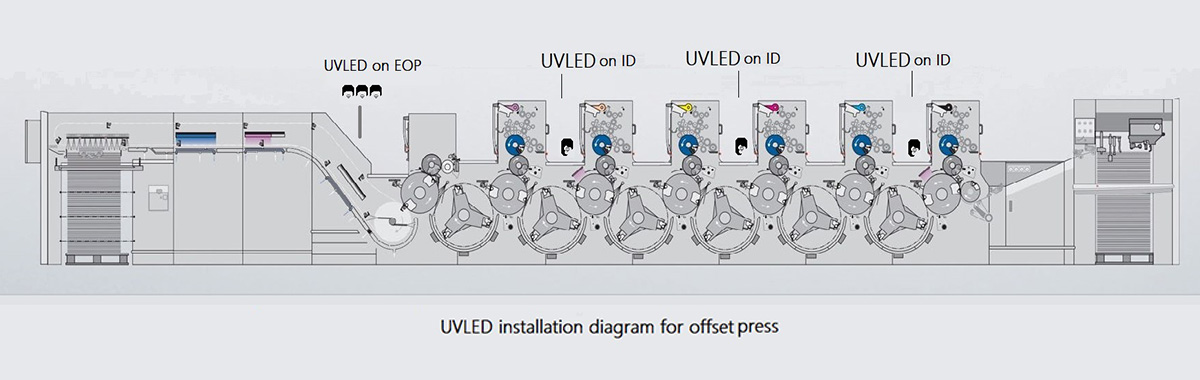

In the printing industry, UV/LED curing systems are widely used for ink drying in offset, flexographic, and digital printing processes. The instant curing ability of UV/LED systems enables faster printing speeds and reduces the risk of smudging or bleeding. Moreover, the use of UV-curable inks eliminates the need for solvents, leading to better print quality and reduced emission of air pollutants.

In the automotive industry, UV/LED curing systems are employed for the fast and efficient drying of paints and coatings. These systems ensure a high-quality finish and eliminate the need for time-consuming thermal drying processes. Moreover, UV/LED-cured coatings exhibit excellent resistance to scratches, chemicals, and weathering, enhancing the durability and longevity of automotive finishes.

In the electronics industry, UV/LED curing systems find application in the production of printed circuit boards (PCBs) and semiconductor devices. UV/LED systems enable rapid curing of adhesives, conformal coatings, and solder masks, ensuring reliable and durable electrical connections. The precise control over the curing process provided by UV/LED systems ensures that sensitive electronic components are not subjected to excessive temperatures or prolonged exposure to heat.

In conclusion, UV/LED curing systems provide numerous advantages across various industries. Their high speed, precise control, environmental friendliness, and superior curing capabilities make them an indispensable tool for achieving efficient production processes and high-quality products.

VTECH for winning the "Technological Innovation Award" in the Equipment Category at the 2023

Vtech Co., Ltd. Showcases Cutting-Edge UV Curing Technology at ALLPack & ALLPrint Indonesia 2024

Vtech Exhibits Cutting-Edge UV Curing Technology at The 21st International Plastic, Printing and Packaging Industry Exhibition

Бренд ведущих производителей светодиодных систем отверждения в Китае

Top-Tier UV LED Curing Systems Manufacturers in Europe

Vtech Shines at Drupa 2024, Showcasing Industry-Leading UV Curing Technology

You may also like

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code