Understanding UV Cure Technology: The Key to Efficient Production

Sustainability in Printing: Harnessing the Power of UV Cure Technology

In the world of modern printing, UV cure technology has revolutionized the way printing processes are carried out. This article aims to delve into the depths of UV cure technology, its applications, benefits, and how it can elevate production efficiency, with a focus on Vtech Co., Ltd's innovative UV curing systems.

1. What is UV Cure Technology?

UV cure technology utilizes ultraviolet light to instantly dry and cure inks, coatings, adhesives, and other materials. Vtech Co., Ltd has been at the forefront of developing water-cooled UV curing systems and LED UV curing systems, leading to efficient and reliable production processes.

2. The Science Behind UV Cure Technology

Explore the scientific principles behind UV cure technology, including how UV light initiates a photochemical reaction in the ink or coating, resulting in rapid curing and superior adhesion. Vtech Co., Ltd's UV curing systems, under the brand name WT, are engineered with cutting-edge technology for optimal performance.

3. Advantages of UV Cure Technology

UV cure technology offers numerous advantages, such as instant curing, energy efficiency, enhanced durability, and the ability to cure a wide range of substrates. Understanding these benefits can significantly impact marketing strategies for printing and packaging industries.

4. Applications of UV Cure Technology

From offset press and flexo press to coatings and silk screen printing, UV cure technology finds diverse applications across various industry segments. Vtech Co., Ltd's expertise lies in developing and producing different kinds of UV and LED curing systems tailored to specific printing processes.

5. Vtech Co., Ltd: Pioneering UV Cure Technology

Take a closer look at Vtech Co., Ltd's journey as an industry leader specializing in UV cure technology. With rich experience, numerous patents, and a commitment to innovation, Vtech Co., Ltd is dedicated to providing reliable service and efficient production solutions.

6. Choosing the Right UV Curing System

Understand the key factors to consider when selecting a UV curing system for your printing operations. Compatibility, energy efficiency, and customization options are vital aspects that Vtech Co., Ltd's UV curing systems effectively address.

7. Incorporating UV Cure Technology for Competitive Advantage

Learn how integrating UV cure technology can give businesses a competitive edge in the market. Efficiency, product quality, and sustainability are pivotal aspects that resonate with customers and underline the significance of UV cure technology in marketing strategies.

Conclusion:

In conclusion, UV cure technology represents a paradigm shift in the printing and packaging industry, fostering enhanced efficiency, sustainability, and product quality. With Vtech Co., Ltd's advanced UV curing systems, businesses can elevate their production processes and stay ahead in a rapidly evolving market landscape.

FAQs:

Q: Are UV curing systems environmentally friendly?

A: Yes, UV curing systems eliminate the need for solvents and emit minimal volatile organic compounds (VOCs), making them eco-friendly.

Q: Can UV cure technology be applied to various printing methods?

A: Absolutely, UV cure technology can be seamlessly integrated with offset press, gravure press, flexo press, and other printing techniques.

Q: How does UV cure technology contribute to energy efficiency?

A: UV cure technology significantly reduces energy consumption due to its instantaneous curing process, resulting in lower operational costs and environmental impact.

Q: What sets Vtech Co., Ltd's UV curing systems apart from others in the market?

A: Vtech Co., Ltd's UV curing systems are distinguished by their cutting-edge technology, customized solutions, and proven track record of reliable performance.

The Ultimate Guide to LED UV Curing Light Technology

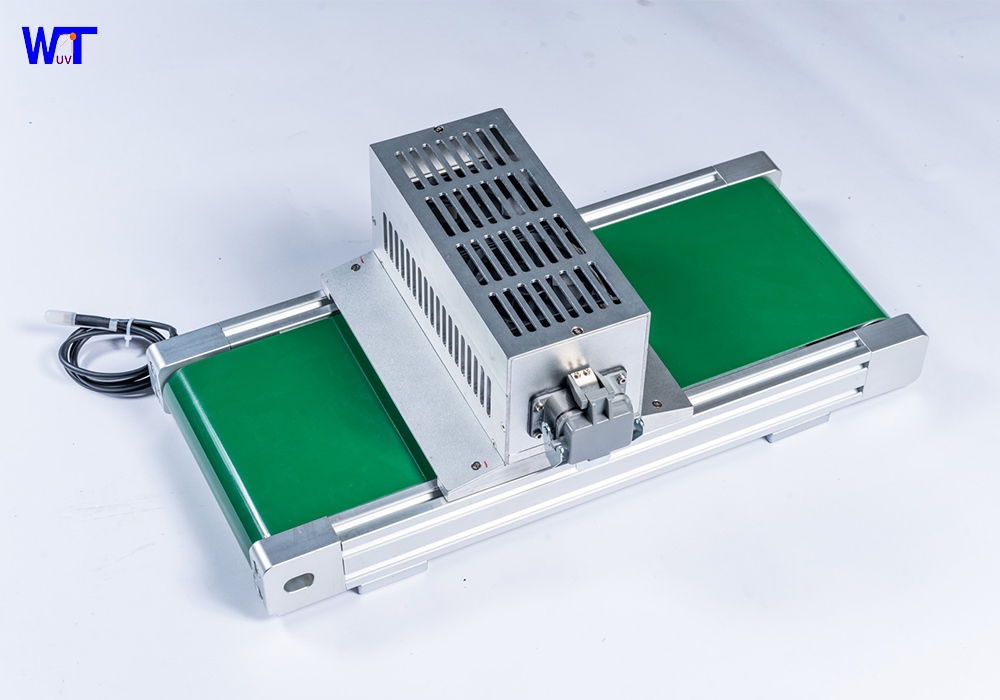

Innovative UV Curing Conveyor Systems: A Complete Guide

The Ultimate Guide to LED Curing: How WT's Innovative Technology is Revolutionizing the Industry

Advantages of UV LED Curing Systems for Industrial Applications

normal

Why and how do I replace a UV led?

How long will take for mass production?

How to cooperate with you and what is the cooperation process?

What's the Peak Irradiance do I need?

What's the cooling way?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code