Understanding the Principle of UV Curing with Vtech Co., Ltd

Introduction

In the world of printing and coating, UV curing has become a game-changer, offering fast and efficient curing of inks and coatings. Vtech Co., Ltd, a renowned enterprise specializing in UV curing systems, is at the forefront of this technological innovation, revolutionizing the industry with its water-cooled UV curing systems and LED UV curing systems.

What is UV Curing?

UV curing, or ultraviolet curing, is a photopolymerization process that utilizes UV light to instantly cure or dry inks, adhesives, and coatings. This process involves the use of UV light sources, such as UV lamps or LED UV lamps, to initiate a chemical reaction in the photoinitiators present in the inks or coatings. As a result, the inks and coatings solidify, forming a durable and high-quality finish.

The Principle of UV Curing

The principle of UV curing revolves around the use of UV light to initiate cross-linking and polymerization reactions in the photoinitiators present in the inks and coatings. When exposed to UV light, the photoinitiators absorb the energy and undergo a rapid transformation, leading to the formation of polymer chains and the solidification of the inks and coatings. This instantaneous curing process eliminates the need for extended drying times, resulting in higher production efficiency and superior quality.

Applications of UV Curing

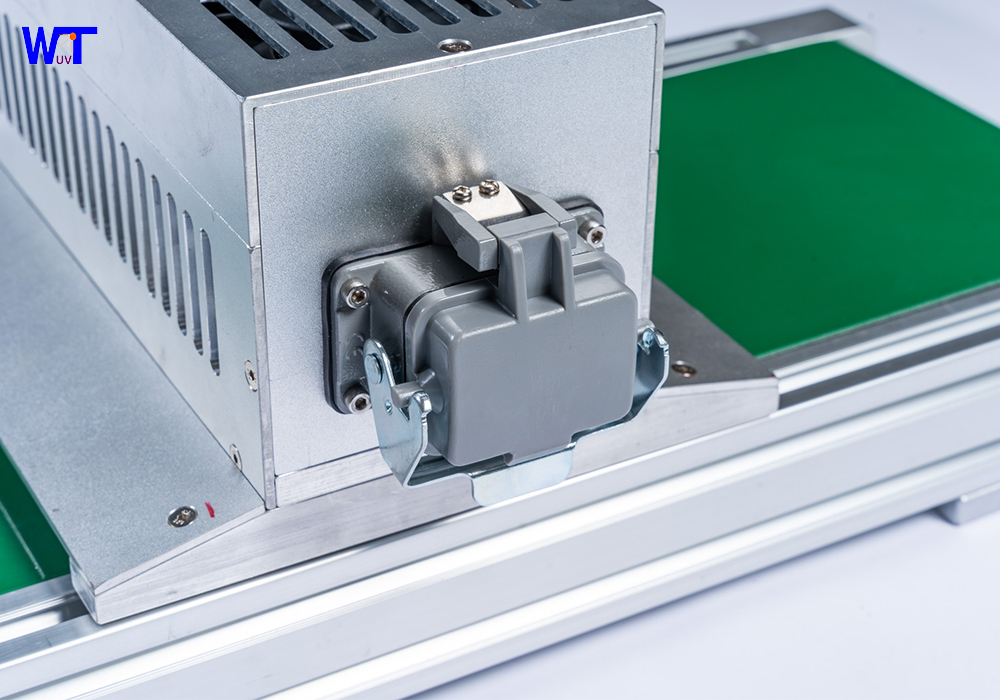

UV curing finds wide-ranging applications in various industries, including printing, packaging, labeling, and coatings. Vtech Co., Ltd, with its extensive experience and expertise, develops and produces different types of UV and LED curing systems suitable for offset press, gravure press, flexo press, and silk screen print. The company's innovative WT brand name is synonymous with reliability and efficiency in UV curing solutions.

Benefits of UV Curing

The adoption of UV curing brings numerous benefits to the printing and coating industry. Firstly, UV-cured inks and coatings exhibit exceptional adhesion, chemical resistance, and durability, resulting in superior finished products. Additionally, UV curing eliminates the use of solvents and significantly reduces volatile organic compound (VOC) emissions, making it an environmentally friendly solution. Moreover, the instantaneous curing process enables faster production speeds and reduces energy consumption, leading to cost savings and improved productivity.

Future of UV Curing

As the demand for sustainable and high-performance printing and coating solutions continues to grow, UV curing is poised to play a crucial role in meeting these industry needs. With ongoing research and development, Vtech Co., Ltd remains dedicated to advancing UV curing technology, offering innovative solutions that drive efficiency, sustainability, and excellence in production processes.

Conclusion

In conclusion, the principle of UV curing represents a transformative advancement in the printing and coating industry, offering rapid and efficient curing solutions with exceptional quality and environmental benefits. Vtech Co., Ltd, with its unparalleled expertise and comprehensive range of UV and LED curing systems, stands as a leading provider in this dynamic field, paving the way for the future of UV curing technology.

FAQs

Q: What are the key advantages of UV curing?

A: UV curing provides superior adhesion, durability, and chemical resistance, reduces energy consumption, eliminates solvent use, and minimizes VOC emissions.

Q: How does UV curing benefit the environment?

A: UV curing reduces the use of solvents and lowers VOC emissions, contributing to a more sustainable and environmentally friendly production process.

Q: What industries can benefit from UV curing?

A: UV curing is widely applicable in printing, packaging, labeling, and coatings industries, offering fast and high-quality curing solutions.

Q: How does Vtech Co., Ltd contribute to UV curing innovation?

A: Vtech Co., Ltd pioneers UV curing technology with its extensive experience, expertise, and development of reliable and efficient UV and LED curing systems.

Q: What makes UV curing an ideal solution for modern production?

A: UV curing's fast curing process, environmental benefits, and cost-effective production make it a desirable solution for modern, high-performance production operations.

The Comprehensive Guide to UV Curing Lamps for Efficient Production

OEM/ODM uv led spot curing system Manufacturers and supplier

The Ultimate Guide to UV Curing Lights: Boost Your Marketing with WT

The Essential Guide to Water-Cooled UV Curing Systems by WT

normal

What materials can UV printers print?

What's the whole UV LED curing system including?

Can you do a design for me or company?

Why and how do I replace a UV led?

lf the light intensity is adjustable?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code