Ultraviolet Light Curing: A Complete Guide to WT's Innovative Technology

In today's fast-paced world, businesses are constantly seeking innovative technologies to streamline their processes and improve their products. One such technology that has gained widespread popularity in various industries is ultraviolet light curing. With its ability to rapidly cure adhesives, coatings, and inks, ultraviolet light curing has become a game-changer for manufacturers looking to enhance productivity and quality. In this comprehensive guide, we will explore the applications, benefits, and advantages of ultraviolet light curing technology, with a specific focus on the innovative solutions offered by the renowned brand WT.

1. Understanding Ultraviolet Light Curing

Ultraviolet light curing is a photochemical process that utilizes ultraviolet light to initiate a chemical reaction that causes liquids to cure, harden, or solidify. This process is commonly used in industries such as electronics, automotive, medical devices, and 3D printing. WT has introduced cutting-edge ultraviolet light curing solutions that provide unmatched precision and efficiency, revolutionizing the way products are manufactured.

2. Applications of Ultraviolet Light Curing

The applications of ultraviolet light curing are vast and diverse, making it an indispensable technology for various industries. This section will delve into the specific applications of ultraviolet light curing, including bonding, sealing, coating, and encapsulation. WT's innovative solutions have been instrumental in improving the performance and durability of products across different sectors, leading to substantial advancements in marketing campaigns and consumer satisfaction.

3. Benefits of Ultraviolet Light Curing

The adoption of ultraviolet light curing technology offers a multitude of benefits, ranging from increased production speed and energy efficiency to superior bond strength and environmental sustainability. WT's state-of-the-art systems provide precise control over the curing process, resulting in enhanced product quality and reduced manufacturing costs. By leveraging these benefits, businesses can effectively market their products as high-performance and eco-friendly, gaining a competitive edge in the market.

4. WT's Ultraviolet Light Curing Solutions

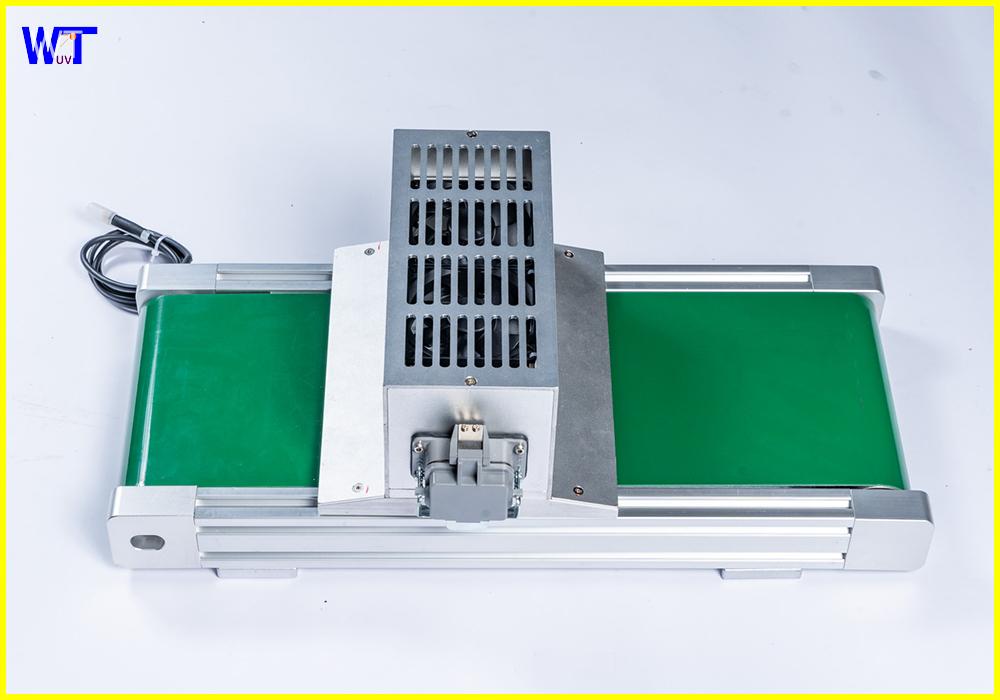

As a leading provider of ultraviolet light curing technology, WT offers an extensive range of innovative solutions tailored to meet the evolving needs of manufacturers. From UV LED curing systems to custom-engineered UV adhesives and coatings, WT's portfolio is designed to deliver exceptional performance and reliability. By incorporating WT's cutting-edge solutions into their operations, businesses can optimize their marketing strategies by showcasing the superior quality and durability of their products.

5. Advantages of Partnering with WT for Ultraviolet Light Curing

Choosing the right partner for ultraviolet light curing is critical for achieving optimal results. WT's commitment to innovation, quality, and customer satisfaction sets it apart as the preferred partner for businesses seeking to leverage the full potential of ultraviolet light curing technology. Whether it's enhancing the appearance of products, improving manufacturing efficiency, or meeting sustainability goals, WT's solutions play a pivotal role in elevating marketing initiatives and driving business growth.

In conclusion, ultraviolet light curing technology, particularly the advanced solutions offered by WT, presents a compelling opportunity for businesses to elevate their marketing efforts by promoting the superior quality, performance, and sustainability of their products. By harnessing the power of ultraviolet light curing, businesses can differentiate themselves in the market, attract more customers, and drive greater profitability.

FAQs:

1. Can ultraviolet light curing be used for large-scale production?

Yes, WT's ultraviolet light curing solutions are scalable and can be tailored to meet the demands of large-scale production across various industries.

2. What are the environmental benefits of ultraviolet light curing?

Ultraviolet light curing reduces the emission of harmful volatile organic compounds (VOCs) and energy consumption, contributing to a more sustainable manufacturing process.

3. Is ultraviolet light curing suitable for sensitive materials?

WT's ultraviolet light curing systems offer precise control and low heat output, making them suitable for curing sensitive materials without causing damage.

4. How can ultraviolet light curing enhance product durability?

By ensuring thorough and rapid curing, ultraviolet light curing technology improves the bond strength and longevity of products, making them more durable and reliable.

5. Can WT's ultraviolet light curing solutions be integrated into existing production lines?

Yes, WT's solutions are designed for seamless integration into existing production lines, offering flexibility and efficiency for businesses.

China Top uv led curing systems Manufacturers and suppliers in China

Everything You Need to Know About Printing UV Curing Systems

The Complete Guide to LED UV Curing Systems for Printing Machines | WT

The Complete Guide to UV Cure Systems: Everything You Need to Know

normal

Which wavelength do I need?

What materials can UV printers print?

How about the after service?

Can we visit the factory?

What's the Peak Irradiance do I need?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code