The Ultimate Guide to UV Light for Curing: How Vtech Co., Ltd Can Help with Marketing

The Ultimate Guide to UV Light for Curing: How Vtech Co., Ltd Can Help with Marketing

In today's highly competitive business environment, it is essential to stay ahead of the curve and maximize efficiency in every aspect of production. UV light for curing has emerged as a powerful tool for enhancing print quality and reducing production time. In this comprehensive guide, we will delve into the world of UV light for curing, its applications, and how Vtech Co., Ltd can help revolutionize your marketing efforts.

Understanding UV Light for Curing

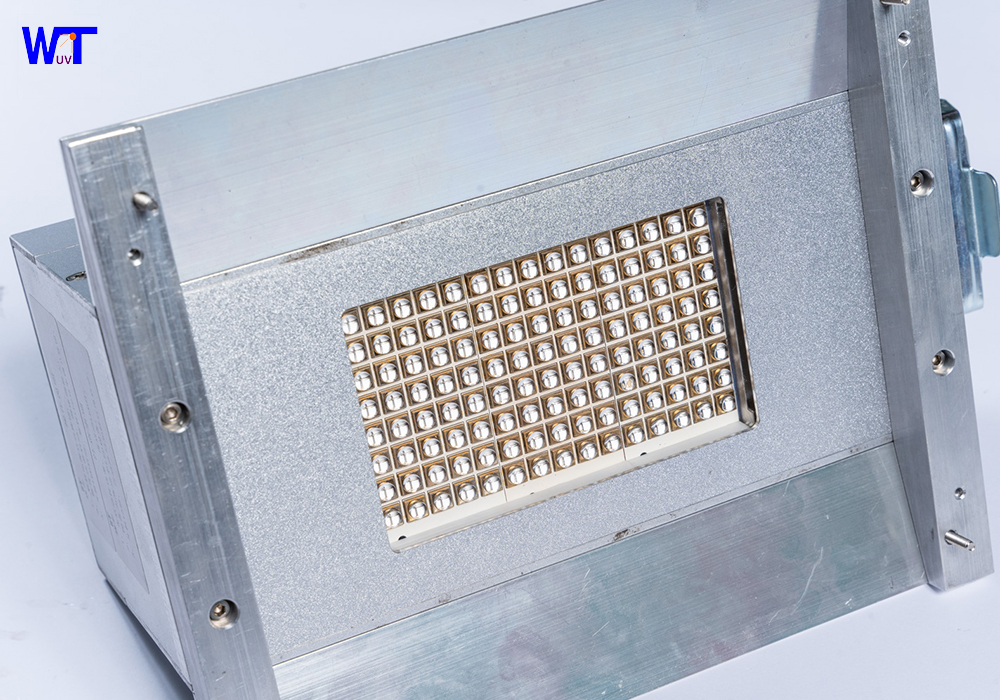

UV light for curing is an innovative technology that utilizes ultraviolet (UV) light to instantly cure inks, coatings, and adhesives. This process not only accelerates production but also produces high-quality, durable finishes. Vtech Co., Ltd has been at the forefront of this technology, specializing in the research, development, and production of water-cooled UV curing systems and LED UV curing systems since 2006.

Applications of UV Light for Curing

The applications of UV light for curing are vast and diverse. From offset press and gravure press to flexo press, coatings, and silk screen print, UV curing systems have the ability to enhance the quality and durability of printed materials. With Vtech Co., Ltd's rich experience and expertise in developing and producing different kinds of UV and LED curing systems, businesses can achieve reliable service and efficient production across various applications.

Benefits of UV Light for Curing

The benefits of UV light for curing are substantial. Not only does it offer rapid curing times, but it also ensures superior adhesion, excellent color vibrancy, and resistance to scratching and fading. With Vtech Co., Ltd's patented UV curing technologies, businesses can elevate their marketing materials, achieving sharper, more vibrant prints that leave a lasting impression on customers.

Vtech Co., Ltd's Solutions for Marketing

As a leading enterprise in UV curing technology, Vtech Co., Ltd offers a range of innovative solutions to enhance marketing efforts. Their water-cooled UV curing systems and LED UV curing systems enable businesses to streamline production, reduce waste, and achieve superior print quality. Whether it's optimizing the efficiency of offset press or elevating the vibrancy of silk screen print, Vtech Co., Ltd's expertise ensures reliable and efficient production.

Empowering Your Marketing Efforts with UV Light for Curing

In conclusion, UV light for curing is a transformative technology that holds the key to enhancing marketing materials and achieving a competitive edge in the industry. Vtech Co., Ltd's pioneering UV curing solutions offer businesses unprecedented opportunities to elevate print quality, reduce production time, and maximize efficiency. By embracing the power of UV light for curing, businesses can redefine their marketing efforts and stay ahead of the curve in today's dynamic marketplace.

FAQs:

1. How does UV light for curing improve print quality?

UV light for curing accelerates the curing process, leading to sharper, more vibrant prints with superior adhesion and durability.

2. What are the key advantages of Vtech Co., Ltd's UV curing systems?

Vtech Co., Ltd's UV curing systems offer rapid curing times, reduced waste, and exceptional print quality, enhancing marketing materials and production efficiency.

3. Can UV curing systems be integrated into existing production processes?

Yes, Vtech Co., Ltd's UV curing systems are designed to seamlessly integrate into various production processes, including offset press, gravure press, and flexo press.

4. How does UV light for curing benefit businesses in the marketing industry?

UV light for curing enables businesses to achieve enhanced print quality, reduced production time, and superior durability, ultimately enhancing the impact of marketing materials.

5. What sets Vtech Co., Ltd apart in the UV curing industry?

Vtech Co., Ltd's rich experience, expertise, and patented UV curing technologies set them apart as a reliable and innovative partner in the UV curing industry.

OEM/ODM uv spot curing system Manufacturers and supplier

OEM/ODM led uv curing systems for printing Manufacturers and supplier

Discover the Latest Trends in UV Curing Systems

OEM/ODM printing uv curing system Manufacturers and supplier

normal

How to cooperate with you and what is the cooperation process?

What's the whole UV LED curing system including?

Are you a trader or manufacturer?

Can you do a design for me or company?

Why choose Vtech's UV LED curing machine?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code