The Ultimate Guide to LED UV Curing Systems for Efficient Production

1. Introduction to LED UV Curing Systems

In this section, we will provide an overview of LED UV curing systems, explaining how they work and the benefits they offer in terms of energy efficiency, reduced heat generation, and faster curing times.

• How LED UV Curing Systems Differ from Traditional UV Curing

We will detail the key differences between LED UV curing systems and traditional UV curing methods, including the technological advancements that make LED UV curing systems more efficient and cost-effective.

2. Advantages of LED UV Curing Systems

Here, we will outline the various advantages of using LED UV curing systems, such as their ability to produce high-quality prints with improved adhesion, reduced waste, and greater environmental friendliness due to their mercury-free composition.

• Energy Efficiency and Cost Savings

We will discuss how LED UV curing systems can significantly reduce energy consumption and operational costs, making them a sustainable and cost-effective solution for businesses.

• Enhanced Productivity and Process Efficiency

We will highlight how LED UV curing systems can streamline production processes by minimizing downtime and increasing throughput, ultimately leading to improved overall productivity.

3. Applications of LED UV Curing Systems

In this section, we will explore the diverse range of applications for LED UV curing systems, including offset press, gravure press, flexo press, coatings, and silk screen printing.

• Print Industry Applications

We will delve into the specific applications of LED UV curing systems within the print industry, emphasizing their ability to deliver high-quality, durable prints on various substrates.

• Coatings and Finishing Applications

We will also cover the use of LED UV curing systems for coatings and finishing processes, showcasing their versatility and effectiveness in achieving superior results.

4. Vtech Co., Ltd: Leader in LED UV Curing Systems

Here, we will provide an in-depth company profile of Vtech Co., Ltd, highlighting its expertise, experience, and commitment to delivering reliable and efficient LED UV curing systems.

• Research and Development

We will showcase Vtech Co., Ltd's dedication to research and development, its numerous patents, and its innovative approach to designing cutting-edge LED UV curing solutions.

• Customer Service and Support

We will emphasize Vtech Co., Ltd's focus on providing exceptional customer service and support, ensuring that clients receive the guidance and assistance they need to maximize the benefits of LED UV curing systems.

Conclusion:

In conclusion, LED UV curing systems represent a game-changing technology for businesses seeking to optimize their production processes. With their energy efficiency, versatility, and outstanding performance, LED UV curing systems offer a multitude of benefits that can drive sustainable growth and success. By partnering with Vtech Co., Ltd, a renowned leader in this field, businesses can harness the full potential of LED UV curing systems and elevate their operations to new heights.

FAQs:

Q: Are LED UV curing systems environmentally friendly?

A: Yes, LED UV curing systems are mercury-free and produce minimal volatile organic compounds (VOCs), making them an environmentally friendly choice for production processes.

Q: Can LED UV curing systems be integrated into existing printing equipment?

A: Yes, LED UV curing systems are designed to be easily integrated into various printing presses and coating machines, offering compatibility and flexibility for businesses.

Q: What is the lifespan of LED UV curing systems?

A: LED UV curing systems have a long lifespan, with thousands of hours of operation before needing replacement, ensuring durability and reliability for consistent performance.

Q: How can Vtech Co., Ltd assist with the implementation of LED UV curing systems?

A: Vtech Co., Ltd provides comprehensive support and expertise to help businesses seamlessly integrate LED UV curing systems into their operations, including consultancy, installation, and ongoing maintenance services.

LED Light Curing Devices by Vtech Co., Ltd

Enhance Your Paint Curing with UV Light: Solutions by Vtech WT

The Ultimate Guide to UV Cure Lights for Efficient Printing

The Ultimate Guide to Ultraviolet Curing Lights: Everything You Need to Know

normal

How to proceed an order for UV LED curing system?

how can we guarantee quality?

How about the after service?

Can you do a design for me or company?

How does your factory do the quality control?

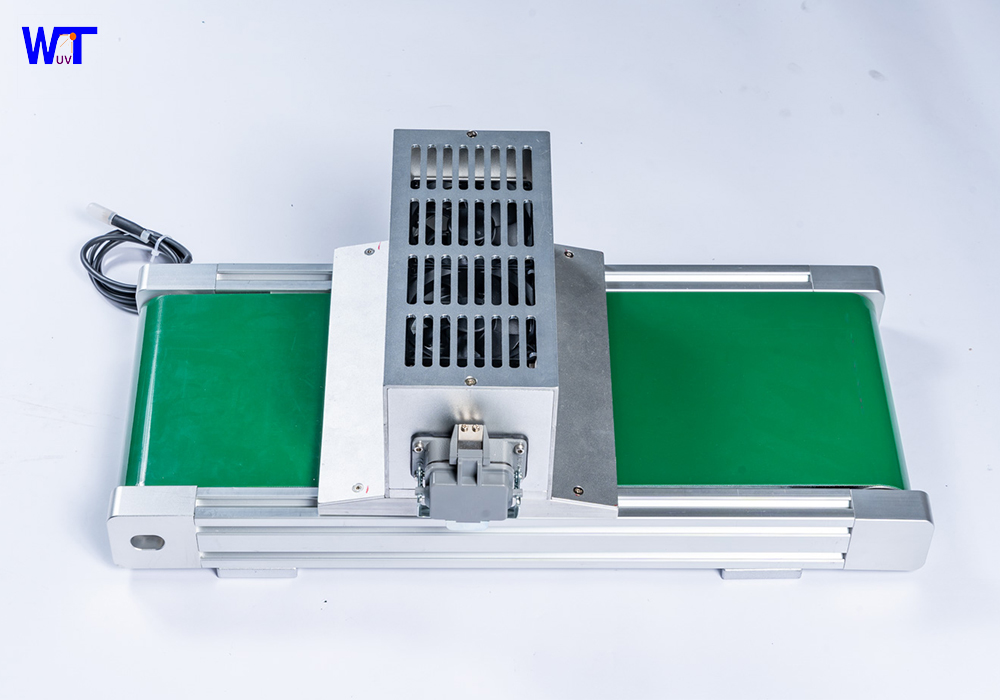

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code