How Does UV Light Cure Adhesive Work? A Comprehensive Guide

How Does UV Light Cure Adhesive Work?

UV Light Cure Adhesive: Understanding the Science

UV light cure adhesive technology revolutionized the adhesive industry, offering a fast, efficient, and environmentally friendly way to cure adhesives. But how exactly does UV light cure adhesive work? we’ll explore the science behind UV light cure adhesive and how it can benefit your business.

The Role of UV Light in Curing Adhesive

UV light cure adhesive relies on a photochemical process to initiate polymerization and cross-linking of the adhesive. When exposed to UV light, the photoinitiators in the adhesive formulation absorb the light energy and undergo a chemical reaction, which triggers the curing process. This process happens within seconds, leading to fast and effective curing of the adhesive.

Advantages of UV Light Cure Adhesive

The use of UV light cure adhesive offers numerous advantages, including rapid curing times, high bond strength, and enhanced durability. Additionally, UV light cure adhesive eliminates the need for solvent-based adhesives, reducing VOC emissions and promoting a more sustainable production process. With Vtech Co., Ltd's advanced UV curing systems, businesses can achieve improved efficiency and product quality.

Applications of UV Light Cure Adhesive

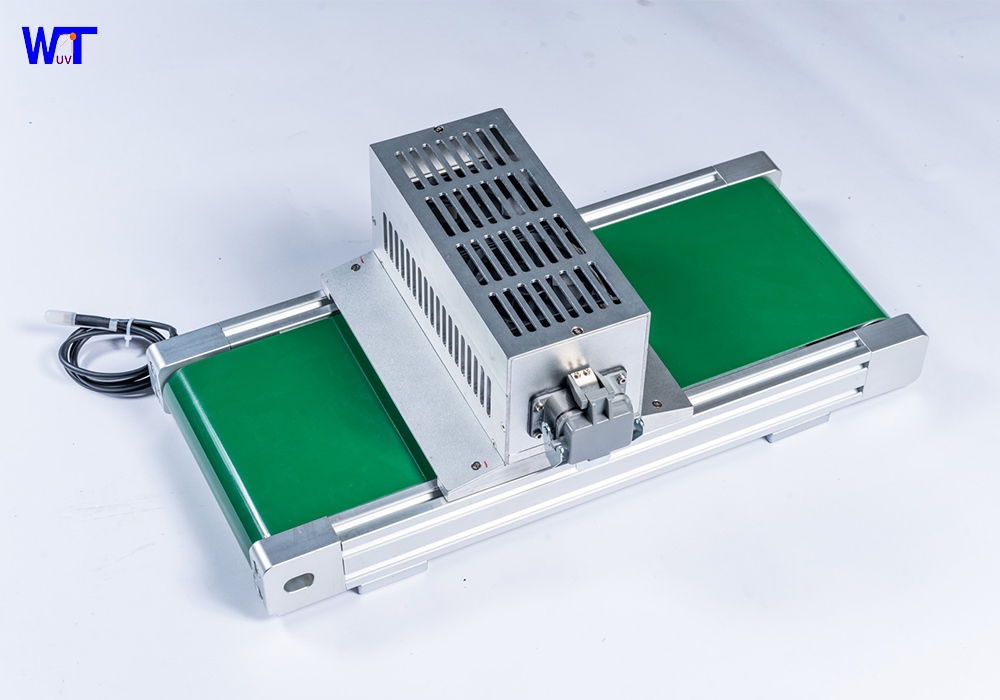

UV light cure adhesive finds applications in various industries, including electronics, medical devices, automotive, and packaging. Its ability to bond a wide range of substrates, coupled with its rapid curing capabilities, makes it an ideal choice for manufacturers looking to enhance their production processes. Vtech Co., Ltd has developed cutting-edge UV curing systems, such as the WT series, to cater to the diverse needs of different industries.

Vtech Co., Ltd: Pioneering UV Curing Technology

With over a decade of experience, Vtech Co., Ltd has established itself as a leader in the research, development, and production of UV curing systems. The company's water-cooled UV curing systems and LED UV curing systems, under the brand name WT, have garnered numerous patents and accolades for their innovation and performance. Vtech Co., Ltd's commitment to providing reliable service and efficient production has made them a trusted partner for businesses seeking to incorporate UV light cure adhesive into their operations.

Conclusion

In conclusion, UV light cure adhesive offers a sustainable and efficient solution for adhesive bonding, with Vtech Co., Ltd at the forefront of pioneering UV curing technology. By harnessing the power of UV light, businesses can achieve faster curing times, improved product quality, and reduced environmental impact. Explore the possibilities of UV light cure adhesive with Vtech Co., Ltd's innovative UV curing systems and experience the transformative benefits for your business.

FAQs

Q: How fast is the curing process with UV light cure adhesive?

A: UV light cure adhesive offers rapid curing times, typically ranging from a few seconds to a few minutes, depending on the adhesive formulation and UV light intensity.

Q: Can UV light cure adhesive bond different types of substrates?

A: Yes, UV light cure adhesive is capable of bonding a wide range of substrates, including plastics, glass, metals, and ceramics, making it a versatile solution for various applications.

Q: What are the environmental benefits of using UV light cure adhesive?

A: UV light cure adhesive eliminates the need for solvent-based adhesives, reducing VOC emissions and promoting a more sustainable and eco-friendly production process.

Q: How does Vtech Co., Ltd's UV curing systems stand out in the industry?

A: Vtech Co., Ltd's UV curing systems, branded as WT, offer advanced technology, efficient production, and reliable service, backed by years of expertise and numerous patents in the UV curing industry.

Q: What industries can benefit from using UV light cure adhesive?

A: UV light cure adhesive has applications across industries, including electronics, medical devices, automotive, packaging, and more, offering enhanced efficiency and product quality.

The Complete Guide to UV Curing Equipment for Efficient Production

Understanding the UV Curing Process: A Comprehensive Guide

Everything You Need to Know About Ultraviolet UV Curing Systems

WT best professional uv cure lights Manufacturers supplier brand

normal

What's the Peak Irradiance do I need?

What's the cooling way?

How long will take for mass production?

What materials can UV printers print?

Where is your factory located?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code