Advantages of UV LED Curing Systems for Efficient Printing

Advantages of UV LED Curing Systems for Efficient Printing

In today's fast-paced world, efficiency is key to staying ahead in the competitive printing industry. With advancements in technology, UV LED curing systems have become the go-to solution for achieving faster curing times, lower energy consumption, and consistent print quality. we will explore the benefits of UV LED curing systems and how they can enhance your printing operations.

I. Understanding UV LED Curing Systems

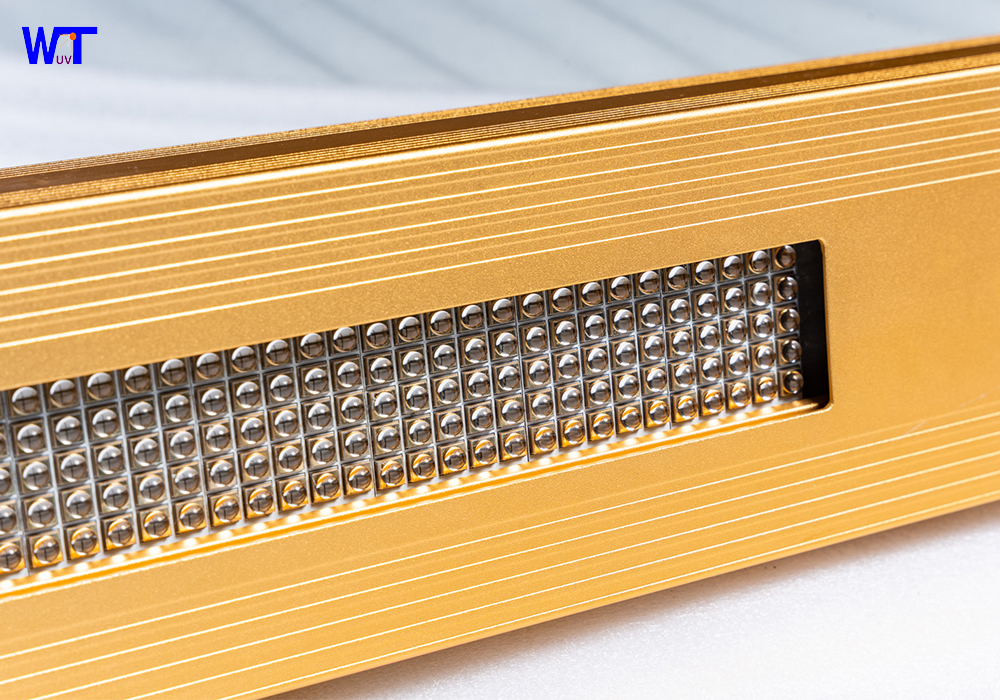

UV LED curing systems utilize ultraviolet light emitted from LED lamps to instantly dry inks, coatings, and adhesives on substrates. Unlike traditional curing methods that rely on heat, UV LED curing systems produce minimal heat, resulting in reduced energy consumption and environmental impact. Vtech Co., Ltd, a leading enterprise in UV curing systems, offers a range of water-cooled and LED UV curing systems under their WT brand, providing reliable and efficient solutions for various printing applications.

II. Faster Curing Times

One of the primary advantages of UV LED curing systems is their ability to achieve faster curing times compared to traditional curing methods. The instantaneous curing process allows for immediate handling of printed materials, leading to increased production output and accelerated turnaround times. With Vtech Co., Ltd's WT brand, you can experience enhanced productivity and seamless workflow integration with their advanced UV LED curing systems.

III. Energy Efficiency

UV LED curing systems are known for their superior energy efficiency, consuming significantly less power than conventional curing systems. The reduced energy consumption not only contributes to cost savings but also aligns with sustainable printing practices, making it an attractive choice for environmentally conscious businesses. Vtech Co., Ltd's WT brand emphasizes the energy-saving benefits of their UV LED curing systems, providing a practical solution for minimizing operational costs and environmental impact.

IV. Consistent Print Quality

Achieving consistent print quality is essential for meeting the demands of today's discerning customers. UV LED curing systems offer precise control over the curing process, resulting in uniform ink and coating application, improved color vibrancy, and enhanced print durability. Vtech Co., Ltd's WT brand ensures the highest level of print quality with their advanced UV LED curing systems, enabling you to deliver exceptional results with every print job.

V. Wide Range of Applications

From offset press and gravure press to flexo press and silk screen print, UV LED curing systems cater to a diverse range of printing applications. Whether you are in the packaging, label, or commercial printing industry, Vtech Co., Ltd's WT brand offers customized UV LED curing solutions tailored to your specific needs. The versatility and adaptability of UV LED curing systems make them an ideal choice for various printing processes, allowing for seamless integration into different production environments.

VI. Company Profile: Vtech Co., Ltd - A Leader in UV LED Curing Systems

Vtech Co., Ltd was established in 2006 and has since emerged as a leading enterprise specializing in the research, development, and production of water-cooled UV curing systems and LED UV curing systems. With numerous patents in the industry, Vtech Co., Ltd has demonstrated a commitment to innovation and excellence. Their UV and LED curing systems are designed to meet the evolving needs of the printing industry, offering reliable service and efficient production for businesses worldwide. Under the WT brand, Vtech Co., Ltd continues to set new standards for UV LED curing technology, empowering printers to achieve optimal performance and print quality.

VII. Conclusion

In conclusion, UV LED curing systems present a multitude of benefits for achieving efficient and high-quality printing results. With Vtech Co., Ltd's WT brand, you can unlock the full potential of UV LED curing technology and elevate your printing operations to new heights. Experience faster curing times, energy efficiency, and consistent print quality with Vtech Co., Ltd's advanced UV LED curing systems, tailored to meet the diverse needs of the modern printing industry.

FAQs (Frequently Asked Questions):

1. Q: Can UV LED curing systems be used for different types of printing processes?

A: Yes, UV LED curing systems are versatile and suitable for a wide range of printing applications, including offset press, flexo press, and gravure press, among others.

2. Q: How does Vtech Co., Ltd ensure the reliability of their UV LED curing systems?

A: Vtech Co., Ltd's WT brand prides itself on rigorous testing and quality control measures to guarantee the reliability and performance of their UV LED curing systems.

3. Q: Are UV LED curing systems environmentally friendly?

A: Yes, UV LED curing systems are known for their energy efficiency and environmentally friendly attributes, reducing energy consumption and carbon footprint.

4. Q: Can UV LED curing systems enhance print quality?

A: Absolutely, UV LED curing systems offer precise control over the curing process, resulting in consistent print quality and improved color vibrancy.

5. Q: How can UV LED curing systems contribute to cost savings for printing businesses?

A: UV LED curing systems consume less power, leading to reduced energy costs and operational expenses for printing businesses.

The Ultimate Guide to UV Ink Curing Systems: A Complete Overview and Benefits

Enhance Your Business With WT's UV Curing Systems

The Ultimate Guide to UV Light Curing Systems for Industrial Use

The Benefits of Large UV Lights: Creating Clean and Safe Indoor Spaces

normal

Can I use my own PLC and Electric cabinet?

How to proceed an order for UV LED curing system?

Can we visit the factory?

How long will take for mass production?

Why choose Vtech's UV LED curing machine?

Offset LED pre-press testing machine

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code