HONGKONG CARBON NEUTRAL TRADING CO.LIMITED Vtech.Co.,Ltd.Guangzhou Water-cooled UV/LED Curing Systems for Printing, Coating and Processing Applications

Product Series

UV LED Curing Systems & Accessories

WT is a professional R&D and production company for water-cooled UV curing systems and LED UV curing systems.

WT has an array of UV lamps and LED products to meet almost any printing or conversion need. All presses can be integrated seamlessly.

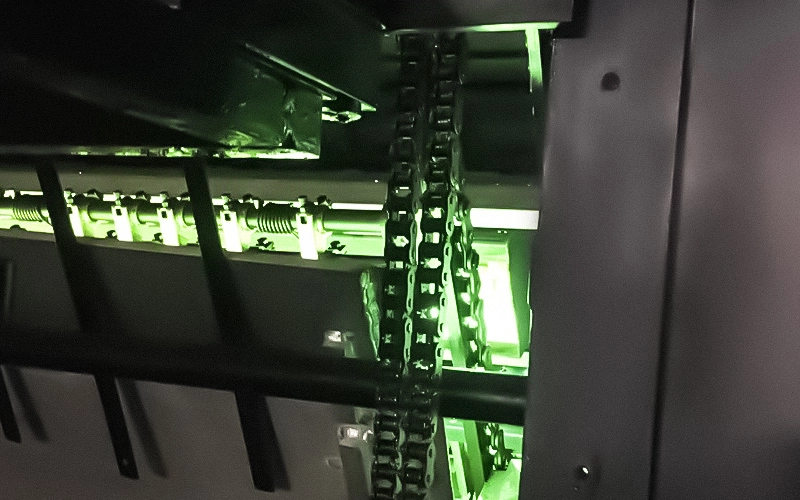

UV LED System

WT's LED water cooling system uses a plane lens, which increases the light intensity by more than 30%; there is no color difference between the ink layers after curing; the paper temperature is kept at room temperature; and the curing is thorough for UV inks.

Tradition UV System

Pioneering the use of water-cooled UV technology in the industry, we provide efficient and reliable UV curing solutions for the printing process. Our UV systems have outstanding applications in various fields, such as offset printing, label printing, gravure press, and flexo.

Cast & Cure

Coating is a key factor of cast & cure which not only protects final products but also offers a high-end and refined appearance. The design of I-Coat module overturns existing apparatus with cylinder which can be repositioned and individual driven for fast plate change and registration.

Sheet-fed Gravure Press

This machine is mainly suitable for cigarette packages and other packaging printing, especially gold ink, silver ink printing, and other large-area ground color printing. It can also undertake UV and water-based coating printing and other security special printing. It can be applied to offset paper.

Our Solution

Tradition UV Systems & LED Drying (Curing) Solution

WT is mainly engaged in the research and development, manufacturing, and sales of UV curing systems and LEDUV curing systems, which can meet almost all printing or conversion needs. WT seamlessly integrates all products to fit your machine.

How We Retrofit :

1. Water-cooled

An advanced water-cooling system ensures prolonged and efficient equipment operation.

2. De-powder spray

Utilizing de-powder spray technology to remove unwanted substances from the surface ensuring print quality.

3. De-lamination

Ensuring a smooth surface of the printing substrate through the de-lamination process.

4. De- preparation time

Minimizing equipment preparation time for improved production efficiency.

5. Cast & Cure

Employing "Cast & Cure" technology, utilizing LED curing to ensure high-quality production.

Sheetfed Gravure Press

Performance characteristics:

1. pneumatic interlocking mechanism, front gauge photoelectric detection, ultrasonic double sheet detection mechanism.

2. A coating module can be added.

UV (ultraviolet) varnishing oil, partial coating, full coating (special order)

IR (infrared) water-based varnish for partial varnishing and full varnishing,

3. The lifting-type paper delivery machine is convenient for operation.

4. Equipped with a roller-type anti-smear device and a blowing and suction box to quickly solve the problem of paper smearing.

5. Variable speed paper feeding mechanism, paper preset, non-stop paper feeding, mechanical double sheet control.

6. Conjugate cam-controlled eccentric up-swing oscillator, down-swing front rule.

7. Brand new appearance design, beautiful and fashionable.

Technical Parameters:

| Max Output | 8000S/H |

Max Printing Area |

700*1000mm |

|

Max Paper Size |

720*1020mm |

Paper Thickness |

80-350g/m² |

|

Max Feeder Height |

1060mm |

Max Delivery Pile |

910mm |

|

Impress CylinderØ |

300mm |

Gripper Margin |

11mm |

|

Net Weigth |

10000kg |

Overall Dimensions (LWH) |

9100*3100*3020mm |

Our Applications

Traditional UV curing solutions for printing & packing

WT has a wealth of experience in the design and manufacture of UV curing solutions across a wide range of applications in the printing, coating, and converting industries.

From the drawing board, WT UV systems are conceived to perfectly integrate into the wider system, working at optimum efficiency and with the highest reliability to reduce operating costs, environmental impact, and unscheduled downtime.

Why us

We are passionate about using technology to make a difference in the world.

With rising energy costs, switching to WT UV LED systems can dramatically reduce your energy usage whilst also reducing CO2 emissions for a positive environmental impact.

10~100%

Automatic adjustment 10-100%.

The UV Lamp output is adjusted by the speed of the press automatically 10-100%.

Lifetime 1500 hours

The lifetime of the UV lamp up to 1500 hours.

1500

50%

Cut energy costs by up to 50%

High efficiency closed outdoor water tower without compressor, using natural cooling principle.

2%

Shorten gripper width to 12mm.

2%

Water-cooled UV/LED System Solution Provider

Professional R & D and production of water-cooled UV curing system, LED _ UV curing system one-stop overall solutions.

01

2006

WT is a company with a history of 17 years of UV/LED Curing Solution Provider.

02

1000+

Experience with over 1000 projects in over 30 countries sets us apart from our competitors.

03

500+

After years of experience and accumulation, we have more than 500 long-term customers.

04

10+

The technical and service team with more than 10 years of experience can quickly respond to customer needs.

Latest News

This article details the 4 core causes of varnish yellowing and provides a full-process anti-yellowing plan covering material selection, process optimization, and storage protection.

This article focuses on two common faults of UV lamps: fusing and bending. It briefly analyzes their causes and provides emergency treatment, repair points and long-term prevention measures, offering practical references for UV lamp use and maintenance.

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Feel Free To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs.

Please contact our experienced team.

We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

On-site Installation

Assign professional technicians to install the service at home.

5-7 days Installation

5-7 days for installation and trial operation of equipment.

5-7 days of Training

5-7 days for operator training and equipment operation and debugging.

365 Days Warranty

Our products are covered by a 365-day warranty.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang